Choosing the right film for a vehicle wrap that caters to the project you are working on can be difficult. But taking the time to select the right film can lead to more efficient installations saving you time and money. To make your decision process easy, we’ve outlined the top eight questions to ask when choosing the right film for your vehicle graphic.

1. What Can be Wrapped?

People assume that everything on a vehicle can be wrapped. However, wrap films are primarily designed to adhere and remove well only on factory-painted panels of the car. Aftermarket paint, preexisting damage, and any signs of touch-up are suspect on the guaranteed performance of any wrap film.

Rubber glazing around windows and silicone caulking, whether painted or unpainted, are also no-go zones. The adhesive will stick during installation, but it is guaranteed to fall off sooner or later. Caulking and rubber are unstable; they expand and contract with very little temperature change. The supple and porous surface does not provide a uniform platform for the adhesive to settle. It is common to see rubber trims oxidize, giving off a soot-like substance that will weaken the adhesive over time.

Hard-to-stick surfaces such as unpainted textured plastic found on bumpers, side trim, door handles, and mirrors require specialty films like DPF 8000™ or DPF 8200. While clients might insist on over these surfaces wrapping over them, keep in mind that these areas take quite a beating and that any wrap over them will be damaged.

2. What is your Budget?

Several factors drive the cost of applying graphics on your vehicle:

- Type of wrap film

- Design work

- Production time, ink, and overlaminate

- Square footage of vinyl

- Complexity

- Labor

3. What types of vehicle wrap films are available?

Most wrap films are made of PVC. Non-PVC or PVC-free films are available, but vinyl is the majority of the market. Then under vinyl films, you can choose between cast or calendered. If you are interested in learning more about Cast vs. Calendered, read more here.

4. How much coverage do you need: cut decal, partial, or full wrap?

The first option is to cut decal. This type of vehicle graphic typically uses cut vinyl such as Series 2100 or Series 5000. Cut vinyl is not printed but come in rolls of solid colors and can be combined to create a multi-color graphic. Compared to printed vehicle graphics that uses ink on white vinyl, the pigments are embedded in cut vinyl that they will retain their vibrancy for up to 10 years!

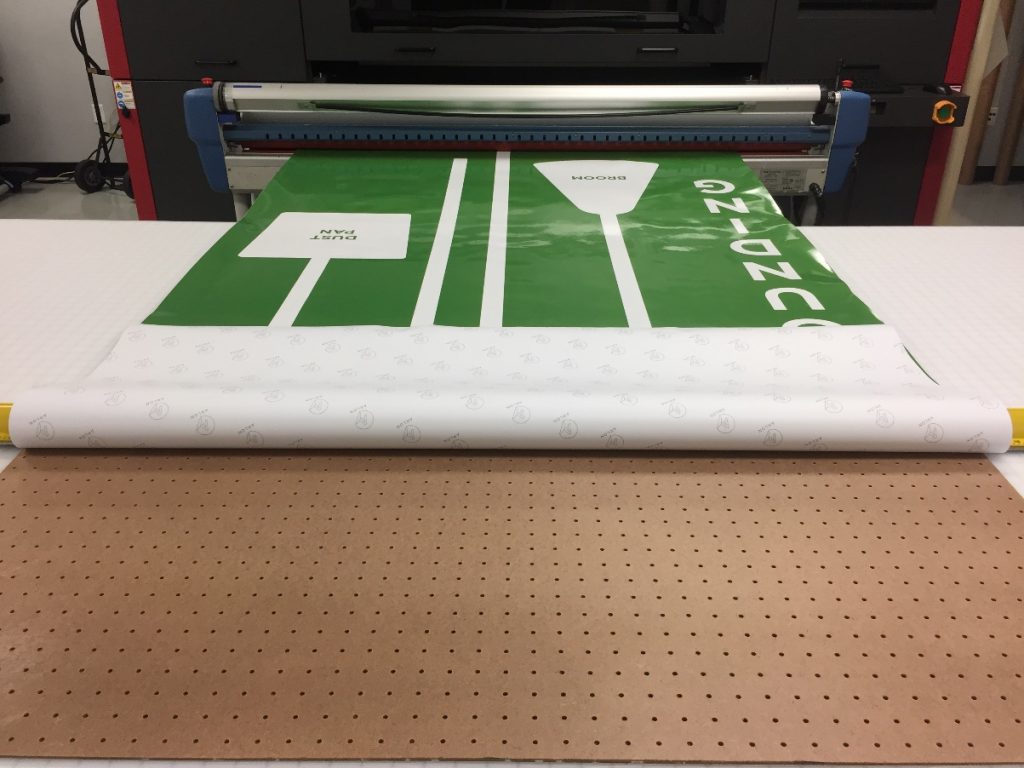

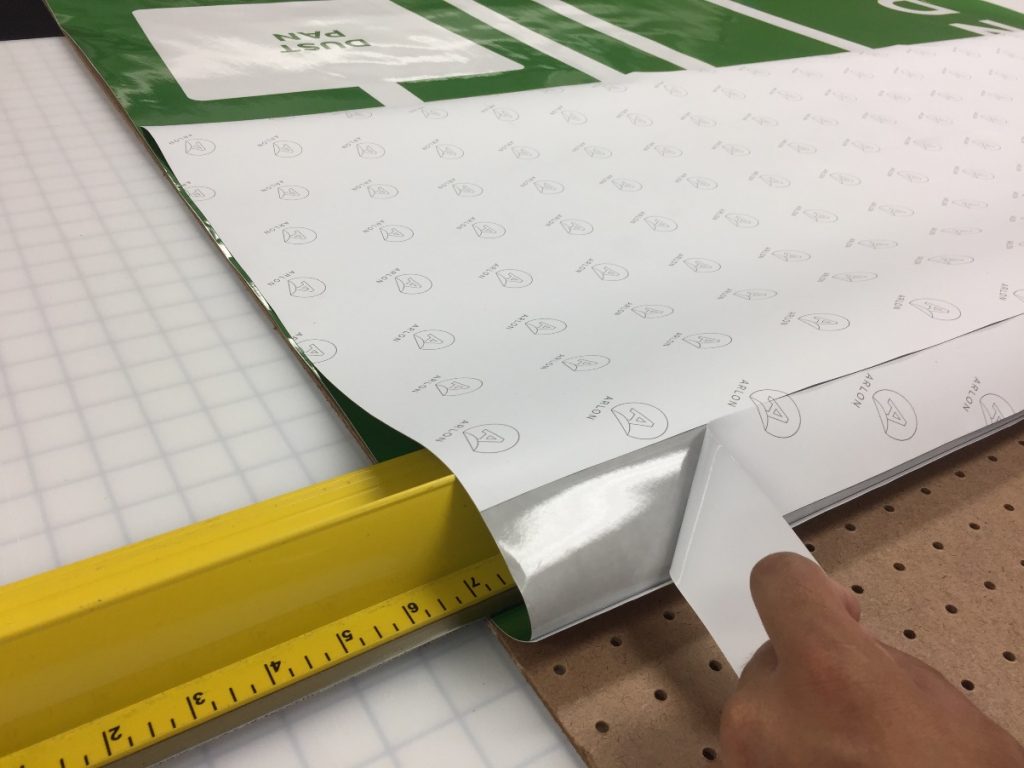

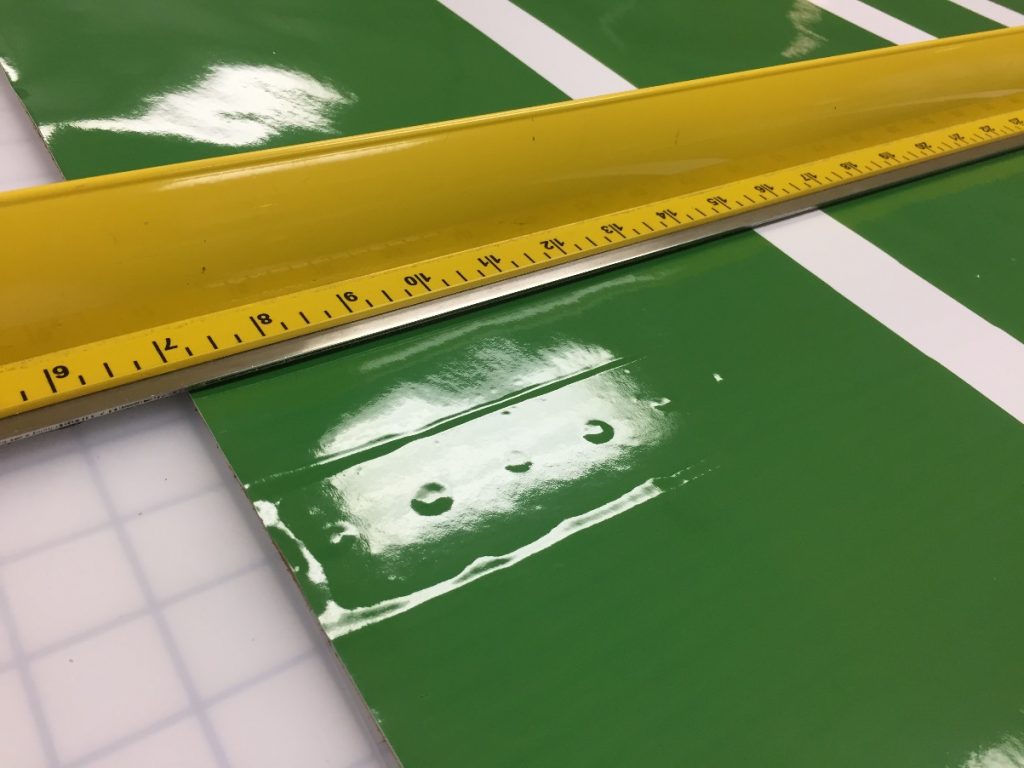

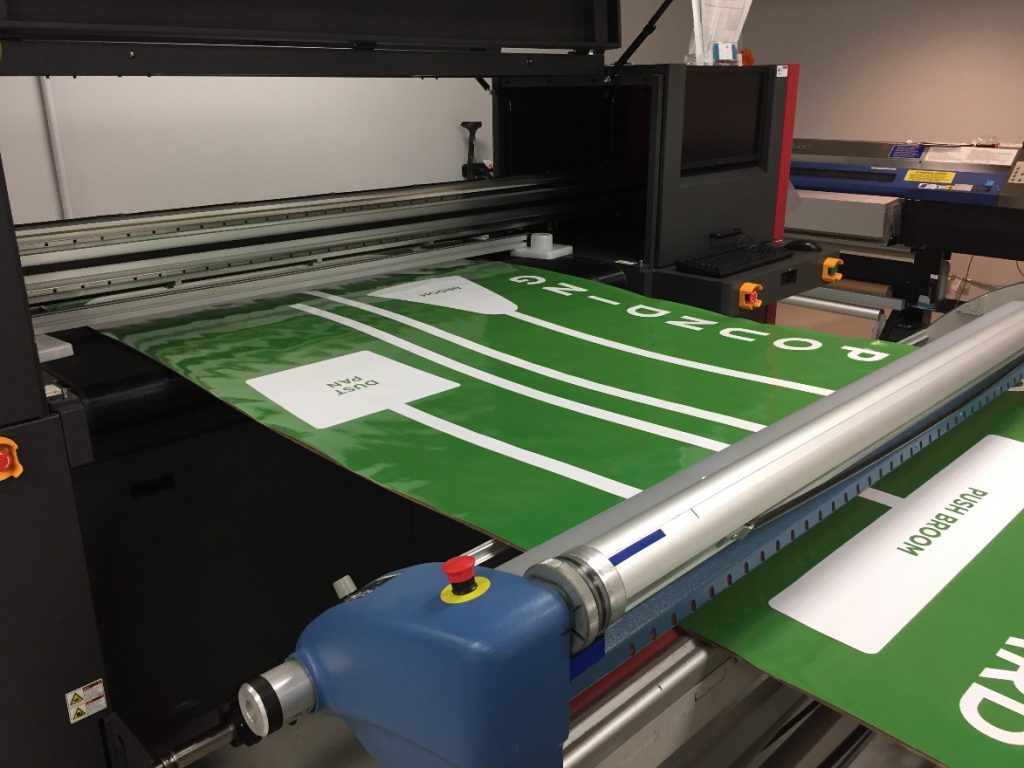

The next option is print-cut graphics or a partial wrap. This graphic leaves the vehicle’s original paint partially visible. A print-cut graphic is like a cut decal, except you need a roll of white printable vinyl and an overlaminate to protect the print. This setup will allow for gradients and custom colors without the need to register multiple single-color vinyl layers. A partial wrap, on the other hand, involves less cutting, masking, and transferring graphics. A large sheet of vinyl is printed, laminated, and applied to the vehicle.

Then comes the full wrap. Some would only call it a full wrap if everything painted on the exterior has vinyl while some will leave the roof, bumper, door handles, and other small parts uncovered and still call it a full wrap. Regardless of the matter, a full wrap covers at least 90% of the “wrappable” area in a vehicle.

5. Do you Need an Overlaminate?

For printed graphics, yes. In this Tech on the Road video, we briefly touch on why you should consider using an overlaminate for your graphics.

6. Do you need it to be permanent or temporary?

In the graphics industry, there are three terms used when describing the longevity of graphics:

- A promotional or short term which is up to 3 years

- Medium-term which is 3-5 years; and

- Long-term or permanent which is 7-10 years

Each vehicle graphic has a specified period in which it can be removed with little to no adhesive residue and without damaging the original paint. Always verify the removal warranty of your wrap with both the shop and manufacturer. Also, it’s important to know that any use of a primer or adhesion promoter will void the removal warranty of a wrap.

7. What does Arlon recommend for partial or full wraps?

A budget-friendly option is DPF 4600GLX, with Series 3420 overlaminate. This film is rated for five years but only on mild curves and relatively flat surfaces. However, if it has to cover an area with some complexity, a more flexible laminate may be necessary like Series 3170, and that also raises it to 7 years. You can also upgrade the base film to Fusion Wrap speed up the installation.

If a vehicle has some deep grooves and sweeping curves, SLX® Cast Wrap will conform the best and without the need for relief cuts or seams. It will be paired with cast overlaminates such as Series 3210 or Series 3220. But for roofs or hoods, anything horizontal, where the vinyl will weather the fastest, use an overlaminate with an extended horizontal warranty like Series 3310.

8. Are you looking for 24/7 Advertising?

Consider using a reflective wrap film like IllumiNITE Wrap® or DPF 2400XLP paired with Series 3210 for a head-turning wrap that won’t miss an impression to a potential client.

Taking the time to learn the right product for your next job is always a good idea, and asking these nine questions when choosing the right vehicle wrap film will be sure to set you up for success. Learn more about Arlon by following our social media channels @arlongraphics.