Wall graphics provide a great opportunity to increase your sign shop’s revenue; they’re mostly straightforward, the surfaces are relatively flat, and they are faster to apply compared to a vehicle wrap. But what about high tack wall films? Unlike other wall films, the tack of these films can create a unique set of challenges. The good news is, we are here to help with our application tips for installing high tack wall films.

Application Tips

Use an Overlaminate

When it comes to walls, the thickness of a high tack film is your friend. Although tackiness is primarily a feature of the adhesive, increasing the film’s thickness will stiffen it. A stiffer film will help reduce pre-tack and prevent pre-stretching.

Thoroughly Clean the Surface

Although some contaminants on the surface may ease the installation process by reducing the tack of the product, you also run the risk of the film failing prematurely.

- Clean the surface by first brushing it dry to knock off loose dirt. Follow it up with a wash either with a sponge and soapy water for painted smooth walls or power washing for exterior textured walls. NOTE: Soap works best as a degreaser because isopropyl alcohol does not wash off oils or grease.

- Rinse and let the surface completely dry.

- For painted smooth walls, wipe the surface with a 50% water/alcohol solution with multiple and heavy passes on the top, bottom, and side edges.

Aim For The Right Surface Temperature

The ideal surface temperature is between 65°F – 90°F (18°C – 32°C). It’s essential to stay the optimal application temperature range for the best performance, but we understand that’s not always a possibility. When applying in colder climates, the risk of the film tearing or shattering is very high. One of the best ways to avoid these issues is to take your time ensuring the proper alignment; this way, you won’t have to reposition the film risking a tear or shatter. When applying in hotter climates, timing is key. Avoid the hottest hours of the day and apply when the sun is down or in the shade.

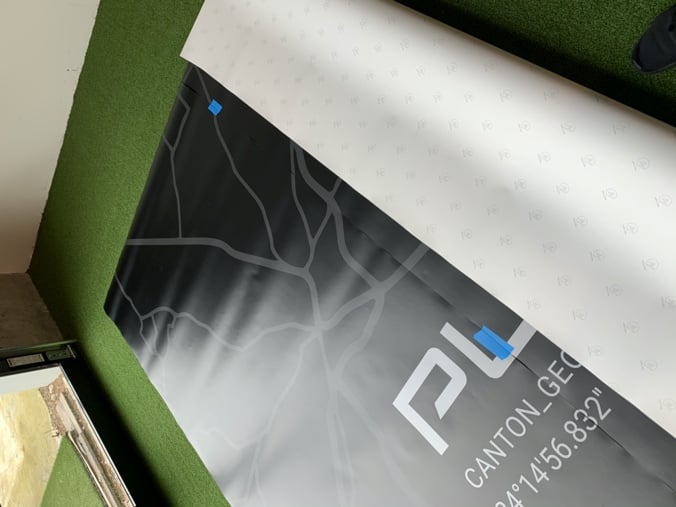

Dry-fitting and Registration Marks

Dry-fitting refers to taping up the panels onto the wall without removing the liner. This step allows you to preview the location of each panel and adjust if necessary. Once all the adjustments are made, create registration marks with a water-soluble pencil or tape.

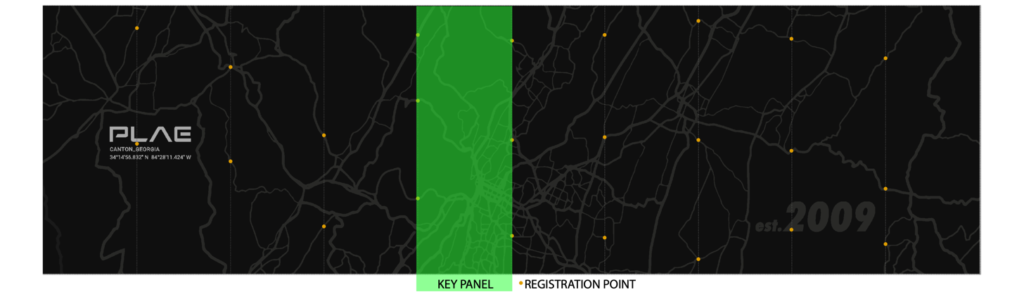

Identify Your Key Panel

In some cases, the first panel does not have any of the design elements to be a proper reference for the remaining panels, like a text that needs to be level with the floor. Consult the mockup to identify your key panel and apply that first. For a more in-depth look into identifying panels, read our Basic Guide to Registering Vinyl Graphics.

Consistent Technique

Having a consistent technique will help you avoid mistakes when applying a high tack film. There are several ways to start your panel–hinge, half-moon, full liner rip, etc.–but whichever method you use, make sure to use the same method and at the same distance from the top edge one for the remaining panels.

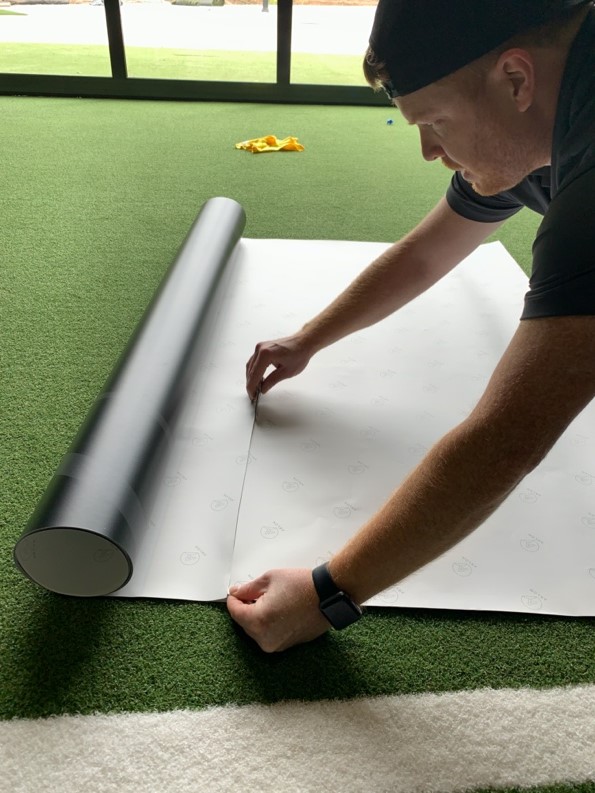

Support the Film’s Weight

Most installers just leave the bottom half of the film hanging as they apply the top half. The problem with this approach is the film’s weight will slowly stretch it without you noticing until it’s too late. Here’s a simple setup with a tube cut in half and zip-tied onto the scissor lift:

Site survey and the Wall/Building Questionnaire

The wall itself can also hinder the application because it has special paint that makes it not receptive to adhesive. So when surveying the site, make sure you use our wall/building questionnaire to aid you in determining the correct product(s) for your project.

Using the right application tips and proper setup will help alleviate any challenges you might have when applying a high tack film. If you’re looking for the right film for your next wall wrap, we’ve got you covered from hard-to-stick surfaces like brick, stucco or concrete to flat wall applications.

Get money back on wall wraps! From now until July 31st, we’re running our Essential Rebate promotion to learn more about what product qualify in your region click the links below.