Placentia, California, April 10, 2024

Arlon Graphics, a global leader in manufacturing innovative graphic materials, is excited to announce its participation in the highly anticipated ISA International Sign Expo 2024. Taking place from April 10th to April 12th, 2024, at the Orange County Convention Center in Orlando, Florida, this event is set to be a pinnacle on the graphic industry calendar. Arlon Graphics is thrilled to showcase its latest innovations, including its exciting, non-PVC, VITAL range, at booths #1746 and #1246.

Arlon Graphics will proudly showcase its premium, cast non-PVC products, DPF V9700 and Series V3370, which launched on March 19th, 2024. These innovative solutions set a new standard in the industry by offering unparalleled performance, durability, and environmental sustainability. Visitors to ISA 2024 will have the exclusive opportunity to experience VITAL firsthand, with live demos and its utilization in Arlon’s Wrap Dash.

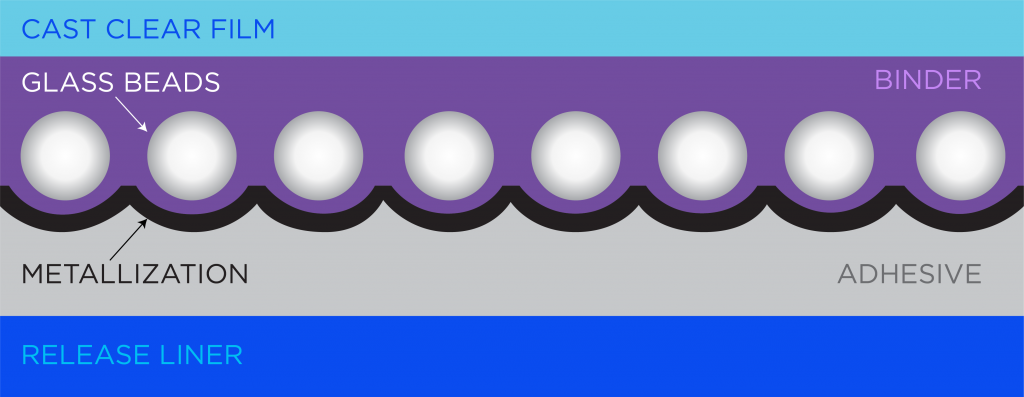

Arlon will be hosting FLITE School at both of their booths, offering attendees a chance to immerse themselves in a hands-on learning opportunity. FLITE School will educate participants on the essentials of FLITE Technology®, Arlon’s proprietary lite contact adhesive system, and participants can earn their wings if they pass FLITE School. FLITE School 1.0 participants can earn Silver FLITE Wings, and new at ISA 2024, Gold FLITE Wings with FLITE School 2.0!

Arlon will also be hosting an exhilarating wrap contest, the Wrap a Rivian contest, at booth #1746, where 8 teams of 2 skilled installers compete in a 3-round, tournament-style wrap battle. Cheer on your favorite teams as they showcase their speed and accuracy while wrapping a Rivian R1T with featured Arlon materials. ISA 2024 attendees are encouraged to watch the competition and will have the opportunity to win prizes.

Additionally, visitors can look forward to competing in Arlon’s Wrap Dash station at booth #1746. Participants can race against fellow ISA 2024 attendees and friends as they navigate through various wrap challenges. The fastest times will be rewarded with awesome prizes.

“We are thrilled to showcase our latest innovations and engage with industry professionals at ISA International Sign Expo 2024,” said Chad Russell, Chief Commercial Officer of Arlon Graphics. “Our dedication to excellence and innovation is ingrained in everything we do at Arlon. We’re excited to demonstrate the breadth of our offerings and share our vision for the future of graphic materials with attendees at our booths.”

Join Arlon Graphics at ISA International Sign Expo 2024 for an unforgettable experience filled with innovation, education, and excitement. Visit booths #1746 and #1246 to discover the future of graphic materials and learn why Arlon is Your Partner of Choice.

About Arlon Graphics

Arlon Graphics is a leading global manufacturer of high-quality graphic materials for the visual communication, vehicle wrap, and wide-format digital printing industries. With a focus on innovation, performance, and sustainability, Arlon is dedicated to producing materials that not only deliver exceptional results but also contribute to a healthier planet. Headquartered in California, USA, Arlon serves customers worldwide, driving the industry forward with groundbreaking products and technical support.

For further information on all Arlon products, visit arlon.com:

U.S.A. Office: 200 Boysenberry Lane, Placentia, CA 92870

Tel: (800) 232-7161, (714) 985-6300; Fax: (714) 985-6305

EMEA Office: Dr. Lelykade 22B, 2583CM Den Haag, The Netherlands

Tel: +31 (0) 70-354-4311; Fax: +31 (0) 70-355-7721

China Office: No. 1989 Xinchang Road, Weifang, Shandong, 262400, China

Tel: +86 0536 6226568